Service Hotline: 0510-86392557

中文| English| Contact Us

| Details: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

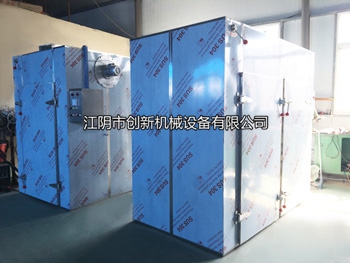

CT-C series hot air circulation oven set the length of similar products at home and abroad, is designed to upgrade several times to reach international advanced level, it is to steam or electricity as the heat source, through the heat exchanger heating by fan forced circulation air. Laminar flow through the hot air drying and the material for heat transfer and evaporation of moisture away materials. According to different requirements of material and drying process of different states, can regulate the amount of air discharge volume and the ratio of circulation to achieve the drying rate increased with the dual purpose of heat utilization, this is the advantages of hot air circulation oven.

To minimize the temperature difference inside the points, in addition to the cycle of relying on forced air convection oven is still outside of the right and left with a sub-style device can be adjusted to regulate the sub-blade angle to the wind before and after the point of the upper and lower box temperature line. Temperature inside the temperature control device can set a constant value in the event of overrun, it will automatically light alarm. Hot air circle oven is intermittent drying rack, large drying equipment versatility, suitable for pharmaceutical, chemical, food, light industry, electronics industry, materials, finished products than temperature, curing, and even bacteria unit operation. Such as: raw material medicine, Chinese herbs, Chinese Herbal Medicine, powder, granule, powder, pill, pigments, dyes, spices, bottles, dehydrated vegetables, food, plastic resin, electric elements, baking and so on. Technical parameters:

Cabinet wall materials are: A3 steel, stainless steel; wall materials: galvanized plate, aluminum, stainless steel; bake vehicle materials are: A3 steel, stainless steel; baking tray materials: aluminum alloy, stainless steel, galvanized sheet |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tel:0510-86392557 Fax:0510-86392554 Mobile : (0)13812157069 Linkman : Jianxin Cai

2016 © Jiangyin chuangxin machine equipment CO.,LTD. All Rights Reserved